A core principle of the mr design philosophy is the pursuit of beauty and honesty through the use of natural materials. the truth and endurance they possess IMBUE projects with a timeless quality that TRANSCENDS their moment in time.

OF THE MANY MATERIALS we use for inspiration WHEN working on the DESIGN CONCEPT FOR a PROJECT, NATURAL STONE IS one of the most important. we LOVE using it FOR KITCHENS, BATHROOMS, STAIRCASES, FLOORS, FEATURE SURFACES AND FURNISHINGS. there are several stones we turn to for such uses, including granite, slate, limestone, marble and QUARTZ AND on occasion, semi-precious varieties like onyx, amethyst or agate. MARBLE IS the MOST commonly requested of these, because of its well-known applications in architecture and design throughout history and the notion that the material can frame the beauty of nature in an elegant, useful and practical way.

when presenting stone for PRIVATE residential projects, we look at our client’s wishlist, budget, and schedule and present options that conform to and enrich the overall concept. these options are sourced from the vast inventory of our trusted local VENDORs and the process is completed during construction, when final slab selections are made in person.

for commercial residential developments, the process is more involved. for these projects, we take into account the client’s goals and present our design in response. there are other considerations that also come into play such as durability and MAINTENANCE and the AMOUNT of material required to FIT OUT the large number of apartment units. high-end residential projects aspire to project a unique standard of beauty AND LUXURY, therefore, materials like marble, onyx, travertine and quartz are the most SOUGHT after because they have beautiful variations in color, patterns and textures.

a great example of this is the collaboration we worked on in 2014 with developers the witkoff group and fisher brothers for their signature tower at 111 murray street in tribeca. this project illustrates the process of design from concept to the selecting AND sourcing of natural stone through to CONSTRUCTION.

the client wanted the residences to pair the comforts of modern living with the highest level of luxury EXPECTED OF their brand. we created a concept for the interiors that is inspired by the industrial heritage of the tribeca neighborhood and the CLASSICAL, iconic new YORK apartments of park avenue through the clean and modern sensibility of the mr aesthetic.

once the design for the residences was set, we directed our attention to sourcing the stone we had proposed. our first step was to meet with local stone vendors and search through their vast inventory of DISTINCT marbles from all over the world. we knew this would become a very significant and UNIQUE component of the project. in addition, we worked with a STONE consultant to advise us on any concerns with quality, durability and potential construction issues of our selections. He also directed us to locations around the world where we could get the best quality and price, which are major considerations when purchasing material for a project of this scale.

in 2015, this research led us first to visit several QUARRIES and production facilities in italy and greece. Such visits allow for the opportunity to see stones in THEIR natural form and understand the characteristics that are inherent to each of them, such as color and veining PATTERNS and variations that can result in great fluctuation between finished slabs. quarry visits are invaluable, as they allow us to identify potential issues with the material before construction begins.

OUR first trip was to a relatively small stoneyard outside of rome. we were there to look at a calacatta borginni marble which we had previewed at a showroom in new york and was a possible choice for the kitchens. this beautiful marble is mostly white with very bold gray veining and USUALLY features secondary, thinner, rust-color veining. it became apparent when we saw the stone in large quantities that it lacked consistency of color and pattern, which was a problem, as our design featured oversized counter and backsplash surfaces. it was decided to search for other suitable marbles. while in italy, we also visited QUARRIES TO SEE STONES chosen FOR OTHER areas WITHIN the project like THE marble FOR feature walls and powder rooms which were to be quite different. these stone yard visits enabled us to understand the production process and the capabilities required to produce the AMOUNT of material we were specifying. they also allowed us to have valuable face-to-face time with the various people that would be involved throughout the PROCESS.

AS THE interior CONSTRUCTION PHASE began, IT BECAME necessary TO VALUE-ENGINEER SOME OF THE MARBLE SELECTIONS to control costs. THIS WAS ESPECIALLY TRUE OF the WHITE MARBLE SPECIFIED for the primary and secondary bathrooms. through extensive research we found a beautiful material CALLED bianco sivec. as this stone is known to show varying DEGREES of patterning, it was important to organize a trip to the quarry in greece to look at it in a large quantity to understand the implications of these variants. there, WE saw that the marble ranges from VERY PURE white with almost no markings to white with a very busy pattern of many markings. these variations depend on the direction in which slabs are cut [from each block.] we identified three variations that were especially suited for all the bathrooms. the PUREST MATERIAL was allocated to the primary bathrooms and a mix of the other two variants, cut into large scale tiles, were allocated for the secondary bathrooms.

we returned to italy LATER THE SAME YEAR TO REVIEW TRAVERTINE FOR THE FEATURE WALLS IN THE PRIMARY BATHROOMS AND A sunset gray marble that WE HAD SPECIFIED FOR THE POWDER ROOMS. on THIS TRIP, we did a REVIEW OF FULL-SCALE mockups to select THE PLACEMENT OF THE CUT SLABS—a very IMPORTANT step WHEN DEALING WITH HEAVILY FIGURED MARBLES. THIS ALLOWed US TO set PARAMETERs FOR THE CONTRACTORS TO follow when installing the stone throughout EACH unit.

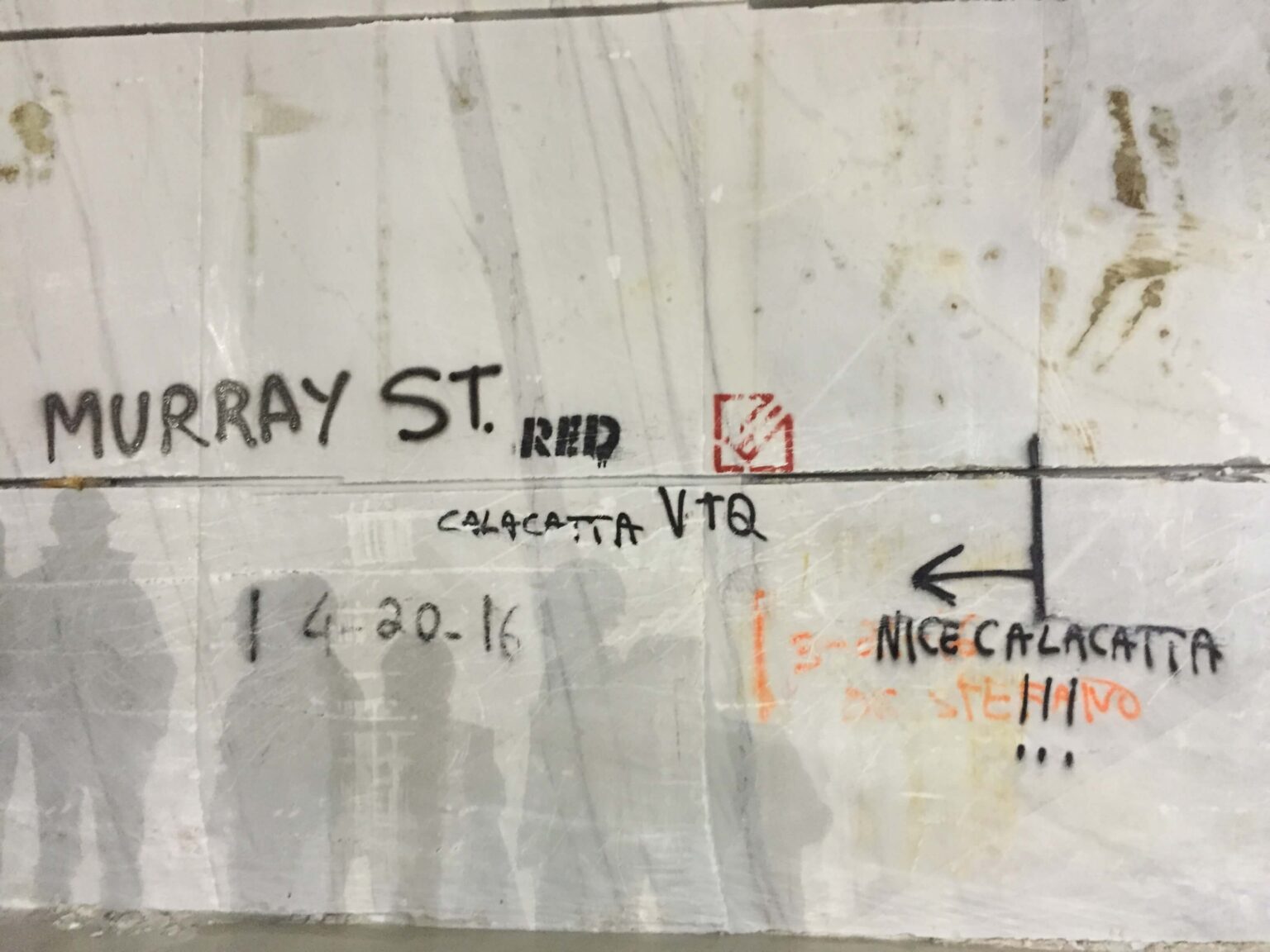

as construction continued, so did the selection process for the kitchen marble. we found a very distinct variant of CALACATTA called calacatta lincoln which is unique and suitable for horizontal and vertical surfaces. it has the bold VEINING expected of most calacatta marbles, but it is uniquely warmer in tone, with AN OFF-white background. it fit our design brief perfectly and felt fresh and luxurious.

in the summer of 2016, we made a visit to a landmark quarry in coloradO, which turned out to be one of our most memorable trips. the ENORMOUS quarry sits deep within the mountains and an entire operation exists right there on site. through the careful process of cutting very large BLOCKS of marble, entire rooms are created, expansive enough to accommodate the OVER-SIZED equipment used to ‘harvest’ the material. the stone harvesting process is a precisely engineered SEQUENCE of steps performed in an extremely controlled manner to protect the stability of the mountain’s geology and to maintain consistency in color and veining. getting the opportunity to visit this quarry, inside of a mountain, in an environment that possesses an otherworldly beauty was an extraordinary experience.

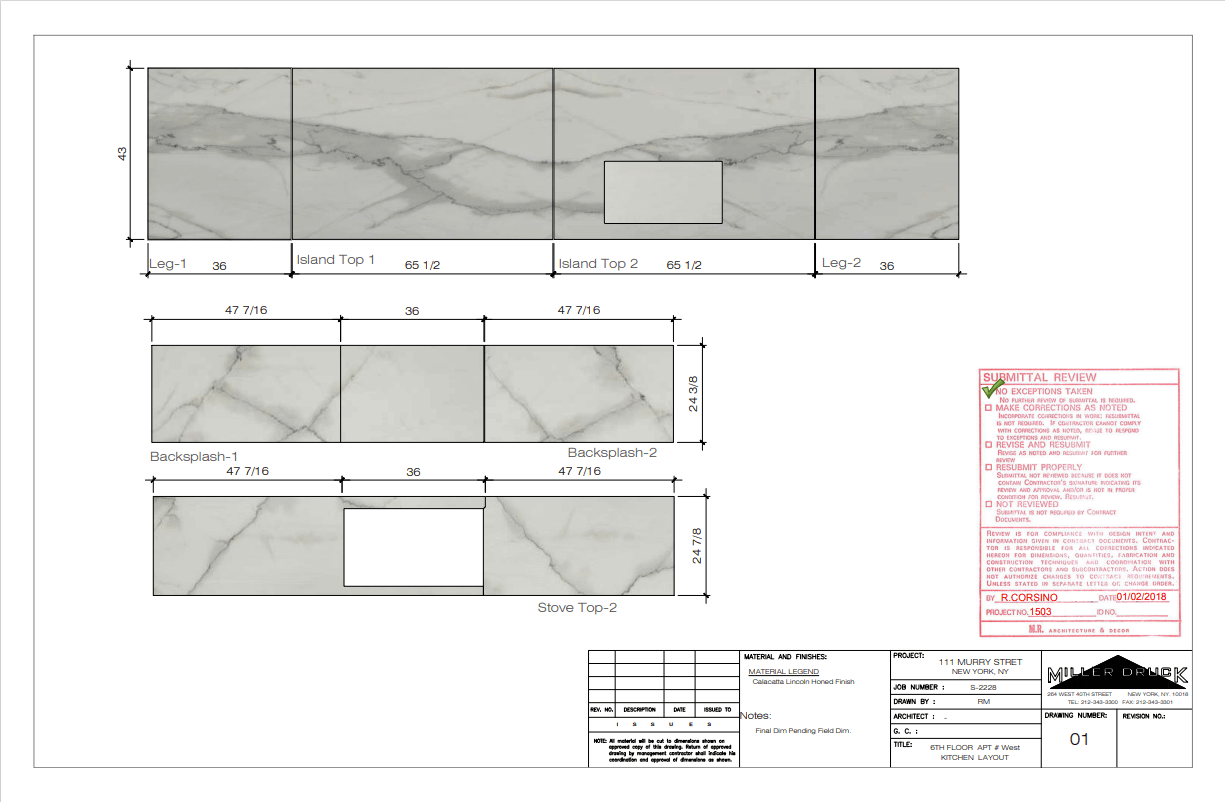

we managed to secure dozens of marble blocks that had the most beautiful characteristics and were available in the sizes we needed in order to minimize vertical and horizontal joints during installation. these blocks were transported VIA FREIGHT train to a stone yard in vermont for cutting. in 2017, we made a trip to this location to review progress. AFTEr slabs were cut, they were sent to our local stone fabricator, miller druck where we began the shop drawing process DURING which each cut of slab is mapped out as we compose the most consistent look for each surface. our design called for as few jointS as possible, AND FOR the pattern to CONNECT seamlessly from one side of the surface to the other, even as it traveled vertically. this is commonly described as vein-match. some kitchens required US TO LAY OUT the stone AND MIRROR the slabs at the joint, WHICH IS KNOWN AS ‘book-match’. once the approval process was FINISHED, the fabricator built all of the counters and surfaces and transported them to each unit for installation.

the opportunity to follow this entire process on a large-scale project like 111 Murray was instructive and rewarding. visting the quarries, stepping into these spaces that exist around and within mountains was a humbling experience, ENABLing US TO SEE nature’s power and the beaUty it possesses. seeing marble in its natural state enriched our appreciation OF the material and reinforced our commitment to findING OPPORTUNITIES IN WHICH to showcase it in our work.